Increasingly, price points, reliability and speed of installation are driving product choices when designing and specifying new developments. “Piping made from multi-layer composite pipe is a viable alternative to copper because it offers flexibility, speed of installation and the elimination of hot works on site,” says Emmeti’s Ireland Sales Manager, Sean Leonard. MLCP has also seen less dramatic price fluctuations in recent years compared with copper and steel. The flexibility of the pipe, together with the use of press fittings, is where MLCP can offer significant savings to developers on installation time. The pipe can be bent readily (including 90-degree bends), allowing efficient routing around the building. Once bent, it retains its form and stays in position. The pre-insulated MLCP Pex al Pex option provides further savings on installation time and cost. MLCP pipe with corrugated sleeve is ideal for supplying feeds to radiators within screeds.

MLCP consists of a plastic pipe (PE-Xb) with an internal aluminium layer that offers rigidity, form retention and a solid oxygen barrier. Emmeti’s MLCP is seam welded, which is stronger than overlapping and maintains a more consistent aluminium thickness. The internal smooth surface prevents limescale and considerably reduces pressure drops. In sanitary systems this also contributes to preventing legionella.

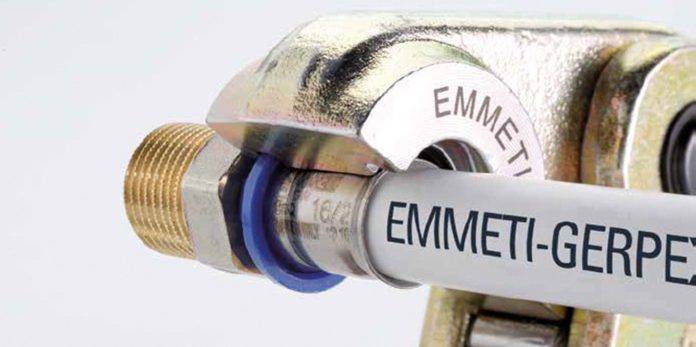

PRESS FITTING

When the pipe is combined with our press fittings, it makes the Gerpex system a complete and highly reliable product with a WRAS guarantee of 50 years. Press fittings are a clean, simple and more efficient alternative to traditional jointing methods such as soldered copper and threaded steel fittings. They consist of engineered brass, with an outer sleeve coating of nickel plating that is not in contact with fluid. The use of a pressing tool to ensure a clean, secure joint means the system can be installed with no hot works on site.

The fittings have a double O-ring system made from ethylene propylene diene monomer (EPDM) rubber. Finally, a plastic ring incorporated into the fitting prevents di-electric corrosion between the aluminium layer of the pipe and the brass-bodied fitting. Compared with conventional plastic piping, MLCP has low expansion characteristics because of the internal aluminium layer. For design and specification purposes, thermal expansion is comparable to copper. Applications of the Water Regulations Advisory Scheme (WRAS) approved system mean it is used regularly within potable environments as well as heating and chilled water systems.

For further information contact Sean Leonard

T: +44 (0)7766 730 559

Alun Coulter

T: +44 (0)7766 730 684

W: www.emmeti.co.uk