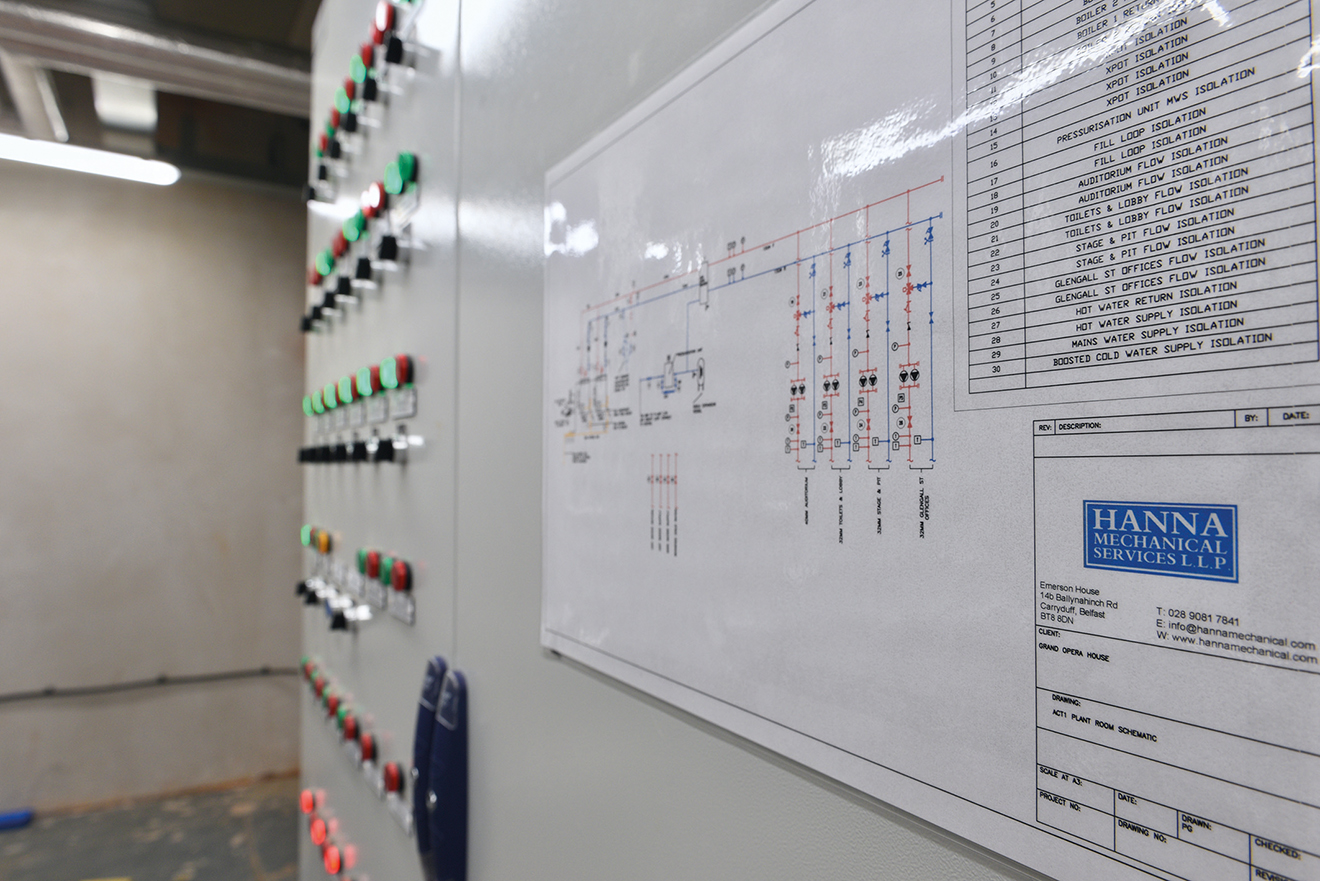

With a remit to provide a “welcoming and comfortable experience for the theatre- going public,” Hanna Mechanical Services overcame huge challenges to bring the HVAC services in the original 19th century auditorium and the 2006 extension up to the standards of a modern day entertainment venue.

Works included the installation of modern new washroom facilities, and new heating system for the main auditorium, which also involved upgrades to the existing air handling units and comfort cooling. Also installed were underfloor heating, ventilation, air conditioning and domestic services to the main entrance foyer and new comfort cooling to the administration offices.

Very few records of the original building, nor the extensive ad hoc repair and restoration works carried out during its previous 125-year lifespan, exist. To install and coordinate an extensive range of modern services without disturbing the historic fabric of the auditorium which features ornate oriental mouldings and ceiling paintings was a major task. It took weeks of intensive surveys on site, trying to identify routes for services, which would ensure accessibility for future maintenance whilst protecting the building’s heritage.

To achieve this so successfully, the Hanna Mechanical team worked in close coordination with the main contractor, Tracey Bros. throughout the project. This has become a familiar and regular working practice for the Carryduff firm.

Paul Graham, Contracts Manager explained, “We have encountered an increase in the number of contract programmes being shortened, while buildings are becoming more highly serviced. In order to accommodate both of these factors we have found that an early presence on site together with full cooperation and coordination with associated trades and services is essential.”

Established in 2003 by Gary Hanna, Hanna Mechanical Services has gained a wide range of experience in all aspects of mechanical services installations. The firm has built a sound reputation within the industry for the ability to work within tight contract programmes while maintaining a high level of workmanship – the perfect attributes needed to deliver the complex Grand Opera House modernisation job.

Great privilege

This project was always going to be a standout one for Hanna Mechanical and for those who worked on it. Paul commented, “Getting to work on such an iconic building has been a great privilege for us. Seeing not only the public face of the building but also behind the scenes workings of the building has been eye-opening. To be able to modernise the mechanical services within this building has been a pleasure and one that has a Hanna Mechanical name to it will be one to talk about for years to come.

“This is a landmark building in the heart of Belfast, with a great history of providing entertainment to the people of Northern Ireland. Hanna Mechanical Services took great pleasure in ensuring that the public will continue to be entertained in a comfortable setting for many years to come

“Working with Tracey Brothers on this project has been flawless from the opening act to the final curtain. The whole team worked in unison and got over any issues easily along the way. It has been a pleasure to work with them.”

Project team…

Client: Grand Opera House, Belfast

Main Contractor: Tracey Brothers Ltd

Architect: Consarc Design Group

Project Manager: WH Stephens

Mechanical Services: Hanna Mechanical Services

M&E Engineers: Semple & McKillop

T: +44 (0)28 9081 7841

E: info@hannamechanical.com

www.hannamechanical.com

Fairhaven H&V Services

Fairhaven H&V Services supplied a range of air terminal devices by Colman Air Distribution to the Grand Opera House renovation project…

A high profile project such as the restoration of the Grand Opera House needs the best quality air terminals, which is why Fairhaven H&V Services, a specialist supplier of ventilation and air movement products, was chosen.

The Moira-based firm supplied an array of air terminal devices from UK manufacturers Colman, including swirl diffusers and linear slot diffusers. Due to the complex challenges of working in an historic building, some of the grilles and plenums had to fit into limited spaces. Working closely with Hanna Mechanical Services’ Contracts Manager, Paul Graham, Fairhaven was able to supply bespoke sizes of grilles and plenums to meet specific requirements. Some of the diffusers were painted to match the majestic internal finishes of the auditorium.

The company offers a wide range of mechanical and natural ventilation systems and components. They provide support to designers, installers and end-users throughout the design and install lifecycle – from providing knowledgeable selection and design advice to expert after-sales support and everything in between.

Commenting on the project, Alan Patterson, Sales Engineer for Fairhaven H&V Services said, “Contributing to the renovation of such an iconic and historically significant local building was a privilege for us. Hanna Mechanical is an excellent company to work with, and we would like to congratulate them on completing this project to a very high standard.”

Fairhaven H&V Services

3 Glenavy Road

Moira

Co. Armagh

BT67 0LT

T: +44 (0)28 92 611648

E: sales@fairhavenltd.co.uk

www.fairhavenservices.co.uk

C&F Quadrant (NI)

C&F Quadrant supplies 2 x 200kW boilers AIC Nesta floor-standing boilers for Grand Opera House restoration project…

Grand Opera House theatregoers will appreciate the upgraded heat comfort levels fuelled by the Nesta condensing boilers supplied by Newtownabbey-based C&F Quadrant.

Michael Clarke at C&F Quadrant said, “We suggested the AIC Nesta boiler for its reliability, efficiency and compact space-saving design and also because it can cascade through a high kW output.”

The extended range of Nesta boilers is specifically designed for commercial and industrial applications. Based on the tried and tested ‘fire-tube’ design heat exchanger, the range of floor-standing condensing boilers is now up to 840kW outputs. The stainless steel heat exchanger provides maximum heat extraction with a minimum footprint. Its corrosion-resistant surface ensures uninterrupted condensing efficiency, low maintenance costs and product longevity.

For added assurance, the boiler comes with a five-year warranty, and a ten-year warranty for the heat exchanger, both subject to terms and conditions.

C&F Quadrant is proud to be involved in the restoration of one of Belfast’s most-loved buildings sayid Michael. “We always pride ourselves in the backup and after-sales service we provide with our boiler systems. Obviously, for a live venue such as the Grand Opera House it is vitally important they can rely on a fast back-up and after-sales service.

He addeed, “Being local, we can provide the fastest response and we have the added benefits of having in-house engineers and a full stock of spares.”

Key features: Nesta floor-standing boiler

• Stainless steel ‘fire-tube’ heat exchanger

• Easy installation and serviceability

• Compact dimensions

• Wide modulation ratio

• Low NOx burner

• Stainless steel internal pipework

• Lightweight casing

C&F Quadrant (NI)

Unit 15

Abbey Business Park

Mill Rd

Newtownabbey

BT36 7BA

T: +44 (0)28 9036 5555

E: michaelc@cfquadrant.com

BSS

BSS once again teamed up with Hanna Mechanical to complete the renovation of the Grand Opera House, Belfast…

Having worked with Hanna Mechanical on a range of prestigious projects such as the Tropical Ravine attraction at Botanic Gardens and the Porsche Centre at Titanic Quarter in Belfast, BSS was primed and equipped to meet the demanding attention to detail expected of a high profile project such as the Grand Opera House renovation.

The company was the main supplier of XPress Copper fittings for the hot and cold-water services and Grundfos commercial pumps; ensuring prompt delivery direct to site of high quality products.

XPress Copper fittings are manufactured from copper and copper alloy, incorporating a black EPDM Ethylene Propylene Diene Monomer O ring and a unique “Leak Before Press” (LBP) design. LBP has been developed to provide instant identification of joints that have been assembled correctly but mistakenly left unpressed. This feature saves time, money and potentially expensive callbacks.

The XPress range delivers all the benefits of a heat-free, press-fit jointing system, providing an easy, fast and highly cost-effective method to create a perfect joint for copper piping. The historic auditorium was designated as a no-hotwork site to avoid potential fire hazards so the XPress fittings were top choice.

BSS operates across 62 locations in the UK and also has an established base in Dublin, so is perfectly positioned to export the high level of service for which the Belfast branch is renowned. Regardless of the size of the contractor or the project, customers in NI or ROI can be assured of receiving a service that is quality driven from start to finish.

Xpress Copper benefits:

• Manufactured from copper/copper alloy

• Available in sizes 12 to 108mm

• Leak Before Press

• Electrical continuity assured when Xpress joint complete

• Clean, heat-free jointing

• Safety, no naked flames, no hotwork permits or costly insurance

BSS

36-38 Duncrue Road

Duncrue Industrial Estate

Belfast

BT3 9BP

T: +44 (0)28 9078 4000

www.bssindustrial.co.uk