Underfloor heating has always been desirable for the scope and flexibility which it provides for interior design considerations.

The introduction of many fixing systems has ensured that it can be used in a broad scope of applications, even in areas previously deemed as not suitable for underfloor heating systems. Tradtionally popular for new screeded solid floors, we can now site hydronic underfloor heating almost anywhere – on upper floors and in existing properties, as well as in new builds; and increasingly, we also use it as part of a total solution.

A large proportion of the project enquiries at Myson involve the use of underfloor heating in combination with other technologies, such as radiators, fan heaters and electric heating. It has become very commonplace, for example, to install underfloor heating on the ground floor with radiators for the upper floors.

APPLICATIONS

Underfloor heating has both domestic and commercial applications, with huge benefits for each. It has certainly grabbed the imagination of the rapidly growing self-build market, as the end-user has the option of using ready sourced single room packs which provide the installer with everything they need to install a screed floor hydronic underfloor system in one purchase. This is a cost effective and simple solution to equip getting a single room with underfloor and is also proving very popular for extensions and conservatories.

However, new build is certainly not losing any ground, as developers consider underfloor more frequently as a routine option. Solid or screeded floors are still a very popular and straightforward option. Hydronic pipe is laid in a looped pattern on insulation above damp-proof and protective layers which cover the sub base. The pipework is anchored using a suitable anchorage system such as Myson’s Tackernail fixing system, before a screed is laid over the pipework to complete the installation.

However, we can also fit underfloor heating over suspended floors, using pre-grooved aluminium diffuser plates to carry the pipework and spread the warmth evenly across the floor and into the space above. This involves cutting small notches in the joists to accommodate the grooves for the pipework.

We also have a very good option for the floating floor, which has a low thermal mass and offers a swift response time to changes in temperature. In these applications, the hydronic pipework is laid in aluminium diffusion plate, within grooved extruded polystyrene panels, with the grooves spaced at 200mm intervals and pre-grooved turning channels for the pipework.

Retrofitting underfloor has relatively recently become a very viable option, thanks to the arrival of Myson Microboard which, at just 18mm deep, carries hydronic pipe such as Myson’s PexCellent pipe, without causing any significant change to the floor height. This also dramatically reduces installation time and labour costs, making underfloor a very attractive method in many more applications, especially in established properties.

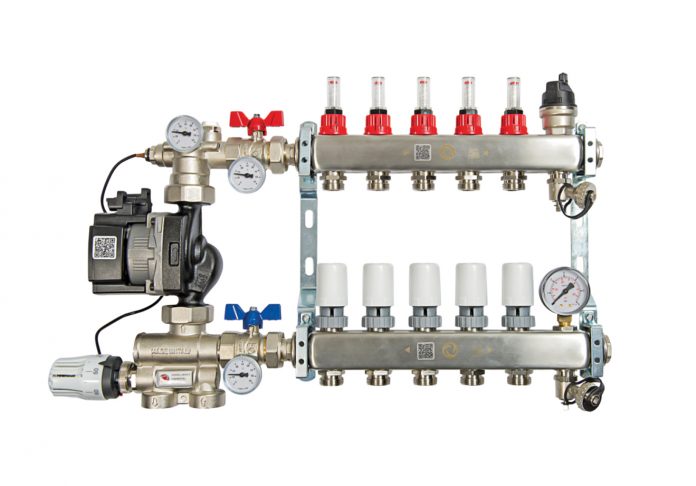

However, it’s not just the fixing systems that are a vital component in an underfloor heating system. The use of controls are also vitally important to get the most out of the system. Each system requires at least one manifold, control centre, wiring centre, actuators and thermostats, with the underfloor heating manifold being the central point, responsible for distributing mixed water provided by the manifold control centre to each heating circuit.

For further details about Myson’s comprehensive portfolio of solutions, visit www.myson.co.uk or contact Sean Leonard on 0044 7766 730 559 or Alun Coulter on 0044 7766 730 684 or visit