Murphy and Kelly’s expertise was called upon for the mechanical element of the new nursing home at Peamount Hospital, a project that consisted of a new two storey 100 bed facility constructed on the existing hospital grounds. All of the new bedrooms have their own ensuite, while a canteen, kitchen, dirty and clean utilities, day wards and first floor level plantroom complete the brief. The mechanical services package for the new nursing home included the complete installation of water services, soils and waste drainage, gas, LPHW heating, medical gases, air handling units, ventilation and air conditioning, installation and coordination of a main plant room, BMS controls and full coordination of all mechanical and electrical installations throughout each ward. The construction firm on this project was Duggan Brothers, while the consulting engineer was Homan O’Brien. The excellent relationships that Murphy and Kelly has built with these two companies ensured the project was completed on time and to budget.

For a company as experienced as Murphy and Kelly, this was not an insignificant project. Several challenges cropped up during the build and although a solution was found for each one, the project still required close attention to detail and constant monitoring on the part of the company. Dean Kelly, Contracts Manager at Murphy and Kelly, said the construction of the plant room was always going to be tricky.

“A congested plant room was always going to be a challenge with the quantity and size of all the plant items. By using our role as lead coordinators we worked to prioritise all available space for plant access and maintenance and with this goal in mind, we generated detailed design layouts to achieve optimum floor space, service access and clearances. That allowed us to eliminate any wasted time, money and manpower caused by in-field mechanical system clashes. Like all the projects we undertake, the finished plant room installation is a source of pride for us.”

These detailed drawings were used by the Murphy and Kelly team to fabricate all of the plant room pipe work, headers and valve arrangements in its Thomastown-based workshop. “This allowed us to progress the onsite installation well ahead of programme once the plant room was constructed. It also allowed us to progress our testing and commissioning, allowing us maximum time within the programme for this critical phase of any project.”

The company poured its 30 years of experience and knowledge into this project and the results speak for themselves. “This is another project we can be proud to add to our ever-growing portfolio.” At the time of interview, Dean and the team were completing the last few items on site and ensuring the completed project met their stringent quality levels. Maintaining quality throughout the project was also a key objective for Murphy and Kelly. This was achieved by the project manager filling out QA sheets on a weekly basis, which were then verified by Dean. “This is typical to all our contracts. I3pt cert central was the assigned certifier on this project and we really embraced their inclusion in the project. We submitted our CVs to them which qualified us to complete our weekly inspections and upload them onto the cert central app for inclusion into the formal register. These inspections could then be viewed by the entire design team and commented on. Any issues raised were then rectified.” Dean says this method ensured everyone on site remained committed to quality and certification on a daily basis.

Murphy and Kelly’s commitment to providing only the highest standards of workmanship on every project it undertakes is evident on this project. Upholding a high standard of quality across all of the mechanical works was a key objective for every team member on this project. This isn’t anything new for the firm; as a company, Murphy and Kelly prides itself on being trustworthy and efficient and boasts an extensive client base that includes some of the largest main contractors in the country. Embracing change and combining it with experience has led to the constant growth of the company over the last number of years. “We were delighted to be involved with this important project and it’s one that we’re particularly proud of. Creating strong relationships with our clients is important and the level of repeat business we enjoy reflects the quality of our work.”

Murphy & Kelly (Thomastown) Ltd, The Fairgreen, Thomastown, Co. Kilkenny.

T: 00353 (0)56 7724294

E: info@murphyandkelly.ie

W: www.murphyandkelly.ie

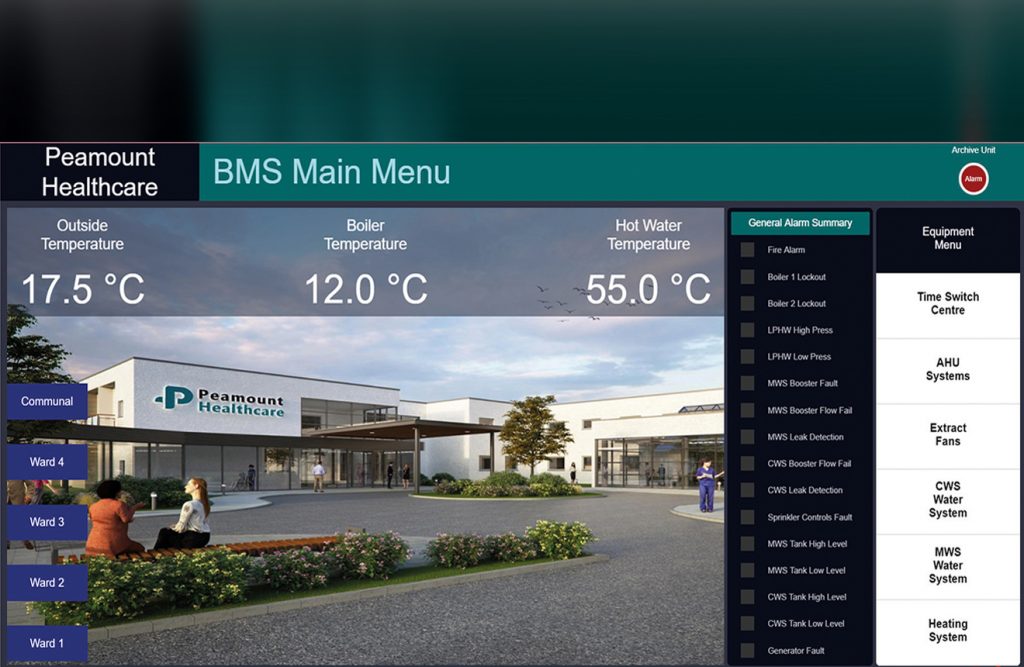

The company has supplied control systems to some of the most prestigious buildings in the country across several different sectors and that’s why it was chosen to supply a full Building Management System to the Peamount Hospital project. The system consists of a Delta Controls frontend PC complete with distributed controllers, all centrally linked to a fully customised graphical user interface.

Control Tech Ltd supplied six state-of-the-art motor control centres, providing power and control to all items of plant throughout the building. The open protocol system allows all mechanical plant to seamlessly integrate and provides the end user with a single access point to efficiently manage and monitor the building performance and energy consumption.

Control Tech’s bespoke energy management system not only allows the user to monitor the energy consumed on site, but also to set benchmarks and targets of energy usage and measure building performance in real time. The efficient system also includes a prioritised alarm handler connected to various systems throughout the building which enables the user to carry out both reactive and preventative maintenance procedures as required. “A key feature of this building management system is its ability to connect to the user in real time. Alarms notifications are emailed according to their priority and a site specific mobile application keeps the user in control at all time,” said Nigel Hayes, Sales & Business Development Manager at Control Tech.

Thanks to a user configurable report generator, users can generate a variety of automatically scheduled reports from energy management to plant operation. “Once configured the report generates automatically allowing the user to report system status to building operators and finance departments as needed.”

Control Tech works with some of the most advanced manufacturers in the world and is continuously improving its supply chain to bring its clients the best quality and value that money can buy. The company has a dedicated control panel manufacturing facility at its office in Dublin, ensuring ultimate quality control for customers

T: 00353 (0)1 459 4655

E: Nigel.hayes@controls.ie

W: www.controls.ie

Alma Engineering supplied a variety of superior quality valves to the Peamount Hospital project. The specific needs of this project demanded high performance, durable products which Alma provided, consisting of a wide range of ball valves, commissioning valves, non-return valves and mixing valves.

Alma Engineering has been operating for over 40 years. Thanks to a commitment to supplying only the best quality products along with offering excellent technical support, the company is the number one choice when it comes to valves and actuators, ABS pipe and fittings, expansion joints, water and gas meters and fluid control products.

T: 00353 (0)404 64353

E: info@alma-valves.ie

W: www.alma-valves.ie

MIPS installed the medical Oxygen and Vacuum systems in Peamount Hospital. This installation included alarms, pipework and termination points for the required rooms.

This installation was fully tested and certified to meet HTM02-01 and ISO standards. MIPS has worked with Murphy and Kelly on numerous projects and has established an excellent working relationship with the company.

MIPS with over 40 years’ experience is the largest specialist pressurised gas system installer in Ireland. MIPS works for some of Irelands biggest names in the medical, pharmaceutical, industrial and education sectors.

Contact us today to arrange a free survey or to get a quotation.

T: 00 353 (0)1 8250677

W: www.mips.ie

A leading company in the HVAC sector across the island of Ireland, Euro Gas Ltd supplied Peamount Hospital with central heating boilers along with water cylinders for domestic hot water use as specified by design engineers Homan O’Brien & Associates. Two Rendamax R607 boilers, rated at 540KW each, were specified for the project.

Featuring flexible configurations and a clever design, the Rendamax R600 range is ideal for a variety of commercial applications. It also features a stainless steel heat exchanger built for challenging working conditions and is specifically designed for optimised efficiency and performance during its entire lifetime. When it came to the hot water cylinders, Cordivari products were specified for their efficiency and durability. At 1000 litres each, these fully insulated, stainless steel cylinders proved the perfect fit for the job.

Euro Gas Ltd has worked with Murphy & Kelly Ltd on several projects in the past. “We have been working with Murphy & Kelly Ltd for over 20 years. This project ran very smoothly for us, which no doubt was helped by the excellent relationship that we have built up with the company over the years.

We are delighted to be involved with Peamount Hospital and look forward to working on more important projects with Murphy & Kelly Ltd going into the future,” said Kieran Cowman, Technical Sales Director at Euro Gas Ltd.

T: 00353 (0)1 286 8244

E: sales@eurogas.ie

W: www.eurogas.ie

Versatile Group supplies projects all over the country, from small individual houses to the largest construction projects, with its high quality range of heating products. As a trusted name in the heating space, the company was called upon to provide very specific products to the Peamount Hospital.

“With healthcare projects in particular, where safety and care are of paramount importance, temperature and cleanliness need to conform to the latest standards. Traditional radiators are not ideal for facilities of this nature. For this reason, we supplied Zehnder Carboline radiant panels to the Peamount Hospital project,” said Tony Kennedy, Commercial Manager at Versatile Group.

Zehnder Carboline radiant panels are regarded as the market leader when it comes to radiant heating. “Radiant panels sit into the ceiling grid. They free up wall space and there’s no issue in terms of cleanliness as they’re antibacterially treated. There’s also no danger of excessive touch temperature. They are ideal for healthcare environments.”

Versatile group has supplied Zehnder Carboline radiant panels on numerous HSE, Healthcare and Educational projects around the country.

“It’s the materials used in Zehnder Carboline radiant panels that make them so suitable for healthcare projects. The pipe within the radiant panel is encased within a graphite sandwich so there’s no risk of that pipe lifting off the front panel. For the vast majority of HSE healthcare projects currently under construction in Ireland, Zehnder Carboline radiant panels will be used.”

T: 00353 (0)46 902 9444

W: www.versatile.ie

Since 1872, Wilo, which was founded in Dortmund Germany, has evolved from being a local specialist to a global player. An uncompromising customer- driven mindset, immediate market proximity and, in particular, the company’s culture of innovation has made it what it is – one of the world’s leading manufacturers of high tech pumps and pumps systems.

The group, which has a turnover in excess of €1.5billion, over 7,500 employees and operates in more than 70 countries worldwide, has made Dublin its HQ for the Irish subsidiary. Wilo’s HQ is situated in Calmount Park, Dublin 12, where the technical sales and service departments operate along with its distribution and logistics hub, also situated in Dublin.

On the Peamount installation, Wilo Ireland supplied high efficiency circulation pumps on the LTHW and used the Cold Water Booster, SiBoost Smart 2Helix VE1603, on the CWS. This product incorporates high-efficiency stainless steel pump hydraulics of the Helix VE series in conjunction with IE4 IEC motors, fitted with air-cooled built-in frequency converters. It also features integrated dry-running detection with automatic cut-out in the event of low water and is WRAS approved.

Michael O’ Herlihy, National Sales Manager, Wilo Ireland.

T: 00353 (0)1 426 0000

E: michael.oherlihy@wilo.com

W: www.wilo.ie